Earth’s most common building materials, such as steel, concrete, plastics, and aluminum, have enabled skyscrapers and jumbo jets, but space is a whole new territory. The vacuum of space, extreme temperatures, intense radiation, micrometeoroid bombardment, and pervasive dust on the Moon, asteroids, and other planets create conditions far outside the comfort zone of traditional terrestrial materials with which we are familiar.

Space mining ventures and future bases can’t rely on the exact same toolbox we use on Earth; many tried-and-true materials will crack, crumble, or weaken in orbit or on other worlds. In this article, we explore why everyday Earth materials fail or underperform in space, and examine the advanced materials and innovations stepping in to take their place for the next generation of spacecraft, space habitats, and mining equipment.

Earth vs. Space: A Hostile Environment for Terrestrial Materials

Before diving into specific materials, it’s crucial to understand why the space environment is so punishing. Several factors, often acting together, wreak havoc on Earth’s materials:

1. Extreme Temperature Fluctuations

In space, an object in sunlight can heat to hundreds of degrees, while the shaded side freezes to far below zero. On the Moon, surface temperatures swing from about +120 °C in daytime to –170 °C at night. These wild thermal cycles cause materials to expand and contract repeatedly, leading to warping, cracks, and fatigue.

Even the Hubble Space Telescope’s original components suffered “cracks due to thermal cycling” in orbit. A material that survives a stable climate on Earth might break after repeated bake-and-freeze cycles in space.

2. Radiation and Atomic Oxygen

Without the protection of Earth’s atmosphere and magnetosphere, materials are barraged by unfiltered solar ultraviolet (UV), high-energy cosmic rays, and solar wind particles. Polymers and plastics can discolor, embrittle, or erode as radiation breaks their molecular bonds.

In low Earth orbit, “atomic oxygen” (single oxygen atoms from broken O₂ molecules) attacks surfaces, causing corrosion of some metals and rapid erosion of organic materials. Space-grade materials often require special coatings to withstand the oxidative onslaught in Low Earth Orbit (LEO).

3. Vacuum and Outgassing

The near-perfect vacuum of space makes gases and volatile compounds literally boil out of materials. Many plastics, paints, and adhesives contain trace solvents or water that will outgas in a vacuum, contaminating sensitive equipment. This is why astronauts report a “space smell” from airlock vents – it’s materials shedding volatiles. Outgassing can also cloud camera lenses or solar panels with a thin film deposit.

Vacuum also negates convective cooling (overheating electronics) and can even lead to cold welding – clean metal surfaces fusing on contact due to the absence of an oxide barrier; a phenomenon that has occurred in satellite mechanisms.

4. Micrometeoroids and Dust Impacts

Space is not truly empty – tiny meteoroids and orbital debris zip around at tens of thousands of kilometers per hour. Even a paint fleck at those speeds can pit glass or punch holes. Hubble’s retrieved solar panels, for instance, were found to have an average of four holes per square meter after 8 years in orbit, some up to 5 mm across (see image below).

These high-speed impacts can crack coatings and weaken structures. On planetary surfaces, there’s also dust. Lunar and asteroid dust grains are jagged like broken glass and highly abrasive, able to sandblast visors, scratch coatings, and foul joints and seals.

5. Microgravity and Vacuum Effects on Materials

Some materials rely on gravity or air pressure during formation (e.g., concrete curing or certain foams expanding). In microgravity, sedimentation and convection are absent, which can alter how materials set or harden.

Without gravity, bubbles don’t rise out of a mixture, which could reduce strength. Even metals can behave differently: alloys may solidify in unusual microstructures when made in orbit, and a lack of pressure can cause sublimation or evaporation of components during processing.

Common Earth Materials That Fail in Space

Space presents extreme thermal stress, radiation damage, vacuum-induced issues, impact threats, and abrasive dust – a combination any material must resist to be useful for long-term missions. Now, let’s look at how some common Earth materials hold up (or don’t) in these conditions.

Steel and Traditional Metals: Heavyweights Out of Their Element

Steel is the backbone of Earth construction and machinery. But in space applications, plain steel faces multiple drawbacks. First, steel is dense – great for bridges, not so great when every kilogram launched to orbit is precious. Steel can also become brittle in cryogenic cold and might shatter under stress in space. Steel’s usual enemy, rust, is actually not a problem in a vacuum (no water or O₂ to form iron oxide).

However, in low orbit, the presence of atomic oxygen can slowly erode even metals by forming volatile oxides, essentially atomically sandblasting unprotected steel over time. Another concern is cold welding. Although not an everyday occurrence, it has caused trouble in a few cases, such as the Galileo Jupiter probe. Because of steel’s weight and these issues, steel is often replaced by lighter alternatives such as titanium alloys or specialty metals in spacecraft.

Concrete and Construction Materials: Hard Truths in a Vacuum

Concrete is the literal foundation of Earth infrastructure, but can you pour a sidewalk on the Moon? Traditional Portland cement concrete needs water, mixed with cement powder and aggregate, and hardens by a hydration reaction. In the vacuum of space or on a dry lunar surface, water will either boil away or instantly freeze. Ordinary concrete also relies on gravity to settle the mix and on an atmosphere to keep water from evaporating too quickly.

If you tried to mix a bucket of terrestrial concrete on the Moon’s surface, the water would vaporize and the concrete would likely cure into a weak, bubbly mess (if it cured at all). Yet, astronauts may need concrete-like materials for habitats and landing pads. NASA has conducted experiments to see how cement hardens in microgravity, as part of the Microgravity Investigation of Cement Solidification (MICS) project.

These have shown that cement can indeed hydrate and harden in microgravity, but with large air pockets trapped inside, making the material more porous and potentially weakening it. Researchers are also looking at alternative binders for “extraterrestrial concrete”. By using vacuum-friendly binders or sintering local materials, we might be able to create concrete-like building blocks off-world.

Plastics and Polymers: Fragile in the Face of Space

From rubber seals to plastic foils and circuit boards, polymers are everywhere in our technology. In space, however, they quickly deteriorate. UV radiation and high-energy particles can break polymer chains, causing materials to embrittle, discolor, or crack. Other issues include outgassing, as many plastics contain plasticizers or additives that can vaporize in a vacuum, and temperature extremes.

The infamous Challenger disaster on a cold Florida morning was caused by rubber O-rings losing elasticity in low temperatures – a sobering example of how temperature can alter polymer performance unless they’re made of space-rated materials. Replacements are space-age polymers and other engineered materials that can maintain integrity amid radiation and vacuum, which we get into in a bit.

Space-Grade Alternatives: The Materials That Can Take the Off-Earth Pressure

So, what does work? What are the go-to advanced materials enabling modern space missions and future space mining efforts? Here are some of the key players replacing Earth-standard materials.

Titanium Alloys & Aluminium

As mentioned, titanium is a favorite for replacing steel. Titanium alloys (like Ti-6Al-4V, used in aerospace) offer excellent strength-to-weight ratios and remain tough at very low and high temperatures. They also resist corrosion very well – critical for spacecraft that might encounter atomic oxygen or, for planetary probes, chemical exposure. The Mars Perseverance rover, for example, uses titanium in its chassis and the treads of its wheels’ flexures.

The downside is cost, but when you only need a few kilograms for a spacecraft part, the performance payoff is worth it. Aluminum has been a workhorse metal for space structures – it’s lightweight and was used in everything from Apollo spacecraft hulls to modern satellite frames. Aluminum performs much better than steel in many scenarios, but not without problems.

It’s softer and less strong, and can be prone to fatigue under cyclic stress. The thermal expansion of aluminum is also relatively high. In low Earth orbit, it also faces the wrath of atomic oxygen. Despite these issues, aluminum remains hugely important in spacecraft due to its excellent strength-to-weight ratio. Where aluminum couldn’t cut it, engineers have sometimes turned to exotic metals like beryllium.

Beryllium is really stiff, and once it gets below about –300°F, it basically stops shrinking. This property, plus its light weight, allowed Webb’s mirrors to hold their precise shape in deep cold – something an aluminum mirror could not do without distorting. This is a prime example of a high-performance metal (though toxic and costly to work with) replacing a conventional metal to meet space-specific challenges.

Carbon Fiber Composites

Composites (carbon or glass fibers set in resins) can be designed with customized properties: high stiffness in one direction, minimal thermal expansion, etc. They are lighter than metals for the same strength, so satellites often use carbon fiber sandwich panels for their structural walls and instrument booms. These composites don’t expand or contract as much with temperature changes, preserving the alignment of optics.

SpaceX’s Dragon capsule, for instance, uses a carbon fiber structure for its heat shield backplate to endure both the cold of space and the heat of reentry with minimal distortion. The only caution is that some composite resins can outgas; hence, space-grade composites use special vacuum-compatible resins cured in ovens so they won’t emit vapors in orbit.

An advanced category of composite is carbon-carbon (graphite fiber in a carbon matrix), used in ultra-high-temp parts like rocket nozzles and heat shields. While not needed for most mining equipment, carbon-carbon shows how far we can push materials (surviving >1600 °C reentry heat) when Earth materials like steel or aluminum would melt.

Aerogels

Aerogels are remarkable materials that are mostly… nothing. These solids are 90–99% air by volume, typically made from silica or other compounds, forming a sponge-like matrix. Aerogels have two big advantages in space: extreme thermal insulation and the ability to gently capture high-speed particles.

NASA used silica aerogel to insulate the Mars Pathfinder and the Mars Exploration Rovers, and another notable application was on the Stardust mission. Aerogel’s appeal is that it’s light and doesn’t outgas or degrade easily. While aerogels are fragile (like a hard foam), their insulation ability per weight is unbeatable. Future space habitats may utilize aerogel panels for insulation, and lightweight aerogel composites could even serve as micrometeoroid bumpers on spacecraft, dissipating impact energy through their porous network.

Polyimides and High-Performance Films

Engineers also turn to high-performance polymers. One superstar is Kapton, a polyimide film used extensively in space. Kapton remains stable from extremely low cryogenic temperatures up to about +400 °C. It has very low outgassing and resists radiation well, which is why Kapton films are used in flexible circuit boards, cable insulation, and the shiny multi-layer insulation blankets wrapping satellites.

Aside from Kapton, other advanced polymers like PEEK (a high-performance thermoplastic) find use in satellite valve components or pump parts, because they can survive vacuum and radiation without significant creep. Polyimide foam is also used inside spacecraft modules for acoustic and thermal insulation, as it doesn’t outgas.

Another polymer workhorse is Teflon (PTFE) – famously non-stick and thermally resistant. PTFE and related fluoropolymers are used in wire insulation, spacesuit outer layers, and bearing coatings. They handle UV and atomic oxygen better than most plastics (Apollo’s spacesuit outer fabric was fiberglass cloth coated with Teflon, called “Beta cloth,” specifically to withstand lunar dust abrasion and solar UV).

Shape Memory Alloys – Materials That Move Themselves

A category of “smart” materials making waves in space is shape memory alloys (SMAs) – metals (often an alloy of nickel and titanium called Nitinol) with the ability to deform and then return to a preset shape when heated. They enable mechanisms that are simple, reliable, and need no motors – perfect for space, where complexity can mean failure. Unlike one-time melting fuse wires, a Nitinol release can be tested multiple times because it’s repeatable.

Engineers like that SMAs can be “trained” to a shape: they are set in a shape at high temperature, deformed while cool, and on re-heating, they recall the set shape. SMAs have already flown on several satellites for deploying solar arrays and other devices. Another property of Nitinol is superelasticity: it can undergo much larger deformations than steel and spring back perfectly.

This is used in vibration-damping or resilient components that can flex under shock and not crack. For space mining, SMAs might be used in robotic arms or tool changers that can actuate by simply warming a component (perhaps using waste heat). Also, habitats could use SMA vents or valves that automatically open/close with temperature changes, providing passive thermal control.

The key is that SMAs thrive in a vacuum, and they reduce parts count. By addressing deployment and actuation challenges with a material property, SMAs circumvent issues of motors seizing or lubricant freezing.

In-Situ Resources: Sintered Regolith, Metals from Moon Rocks, and More

Perhaps the ultimate replacement for Earth materials in space are materials sourced off Earth. This is the promise of in-situ resource utilization (ISRU), making habitats, shielding, or fuel from local materials. Here are some emerging ideas related to using local resources:

Sintered Regolith Structures

Using microwaves or lasers, regolith can be directly sintered into useful items. Think of paving a landing pad by driving a rover that sinters the ground with a focused microwave beam, fusing a thin layer of dust into a hard ceramic-like crust. This would prevent rocket exhaust from blowing deadly dust clouds.

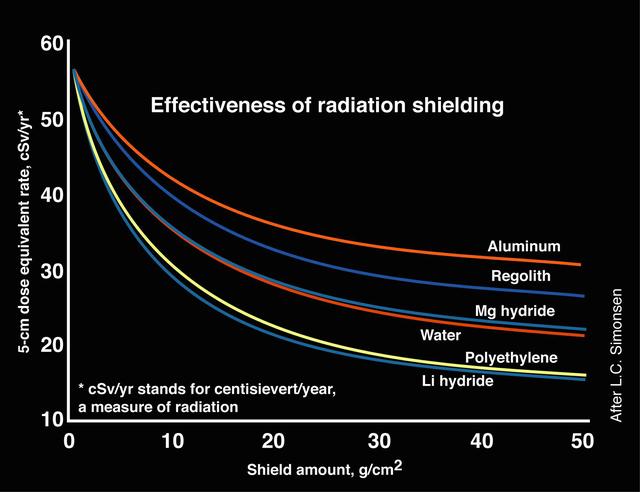

Researchers have also sintered regolith into tiles and rods that can be assembled into walls. Such structures handle the vacuum and radiation as well as the original rocks and are also excellent for radiation shielding, as a thick regolith wall can significantly attenuate cosmic rays and solar flares, protecting crews.

Metals from Moon Dirt

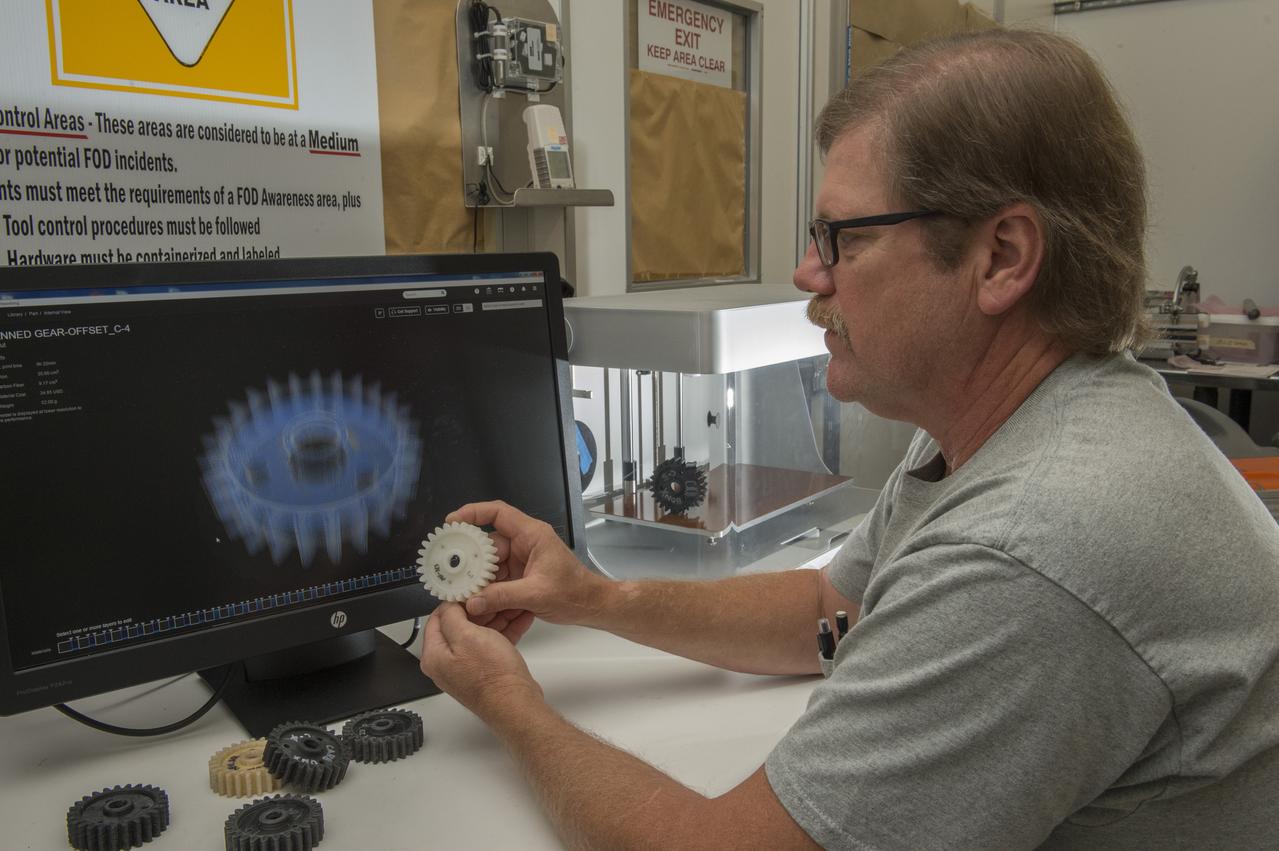

Lunar soil is rich in oxides of aluminum, iron, titanium, and other elements. Future processing plants could extract these metals (via melting, electrolysis, or chemical reduction) to yield aluminum or steel alloy feedstock. One could 3D print or cast structural parts on the Moon itself. The challenge? Metal produced this way might be “unrefined.” For example, lunar iron could be very pure (too soft) or have microalloying from other elements.

Material scientists are looking into how to create useful alloys from regolith feedstock. A concept called “lunar steel” envisions mixing iron from regolith with a bit of carbon (maybe from lunar polar volatiles) to make steel for construction. This steel would obviously be space-rated by default.

Basalt Fiber and Glass

Much of the Martian and lunar regolith is basaltic (volcanic rock). On Earth, we make basalt fiber by extruding melted basalt rock into fibers, similar to fiberglass. On Mars or the Moon, a robotic factory could do the same, producing spools of fiber to weave into composites or insulation.

Basalt fiber is very strong and temperature resistant. It could replace synthetic fibers like Kevlar for certain applications (for instance, as reinforcement in habitat domes or for making pressure vessel overwraps). Since it’s derived from local rock, it sidesteps the cost of hauling up Earth-made fiberglass or carbon fiber.

Water and Plastics from Space

Water ice found on the Moon or asteroids can be split into hydrogen and oxygen, not just for rocket fuel, but potentially to synthesize polymers. Hydrogen and carbon (from CO₂ or other sources) could be used to produce simple plastics like polyethylene on Mars. While this is more futuristic, one could imagine future astronauts “printing” tools out of locally made plastic feedstock, or using a mixture of regolith and a binder made from locally sourced resin.

That way, even polymers for things like habitat interiors might be produced on-site, tuned to withstand that environment (and easily replaceable if they degrade). Importantly, building from local materials also solves the material supply problem. Early demonstrations like the UCF regolith bricks that “are a good candidate for cosmic construction projects” show that it works – you can make durable things out of moon dust.

Innovating for the Future: Material Science Meets Space Science

The march of material science is continuing to open new frontiers for space exploration and commercialization. A few exciting developments on the horizon include:

- Radiation-Hardened Materials: Researchers are developing polymers embedded with radiation-absorbing particles (like tungsten or boron compounds) to use in spacecraft walls. The goal is structural materials that double as radiation shields.

- Self-Healing Materials: Imagine a habitat wall or spacesuit layer that, if punctured by a micrometeoroid, can automatically seal the hole. Self-healing materials – like polymers with micro-encapsulated resin that release into cracks, or metal alloys that can “flow” into a breach under heat – are being researched for space use. Such materials, still mostly in lab stages, take inspiration from biological systems (e.g., bleeding and scabbing to heal). If matured, they could greatly enhance the resilience of space infrastructure.

- Metamaterials for Thermal Control: Advanced structured materials (metamaterials) are being explored to manage thermal radiation in novel ways. This could help keep cryogenic propellants cold or maintain stable temperatures for mining equipment operating in shadowed craters. Similarly, electromagnetic metamaterials might improve wireless power transfer between mining robots and a base, by focusing energy precisely with minimal loss.

- Ultra-strong Fabrics and Cables: For construction in low gravity or space tether systems, materials like Zylon (a high-performance polymer fiber) and carbon nanotube composites are being studied. Future space elevators or tethered orbital launch systems might require materials with tensile strengths an order of magnitude beyond steel, prompting research into weaving carbon nanotubes or graphene into usable cables.

- Dust Mitigation Coatings: New solutions also include electrodynamic dust shields – transparent electrodes on a surface that, when powered, create traveling electric fields to hop dust particles off surfaces. Nano-textured lotus effect coatings (superhydrophobic surfaces) are also being tested to see if they also resist dust adhesion due to reduced contact area. In future lunar mining scenarios, keeping optics, sensors, and solar panels dust-free will be vital.

The Materials Powering Our Leap Beyond

The harsh truth is that the materials that built our civilization on Earth often falter in space. Steel can seize or snap from thermal stress, concrete can’t set without boiling off its water, plastics crumble under radiation, and even trusty aluminum might expand or erode away. But human ingenuity doesn’t stop at Earth’s atmosphere. Scientists and engineers have developed a new arsenal of materials that can survive the vacuum and cosmic extremes.

Every advance in materials extends our capability to not just survive, but thrive in space. Apollo’s hardships taught us and ushered in better-suited fabrics; space telescopes and rovers showcase composites, polyimides, and exotic metals functioning for decades off-world. And as we gear up to build on the Moon and mine asteroids, we’re learning to use what space gives us: turning local resources into air, fuel, and more.

Material science is the silent hero, enabling the next giant leaps. It’s allowing us to replace failing materials of old with space-ready alternatives tailored for the extreme conditions of space.